PTFE for Industrial & Manufacturing Applications

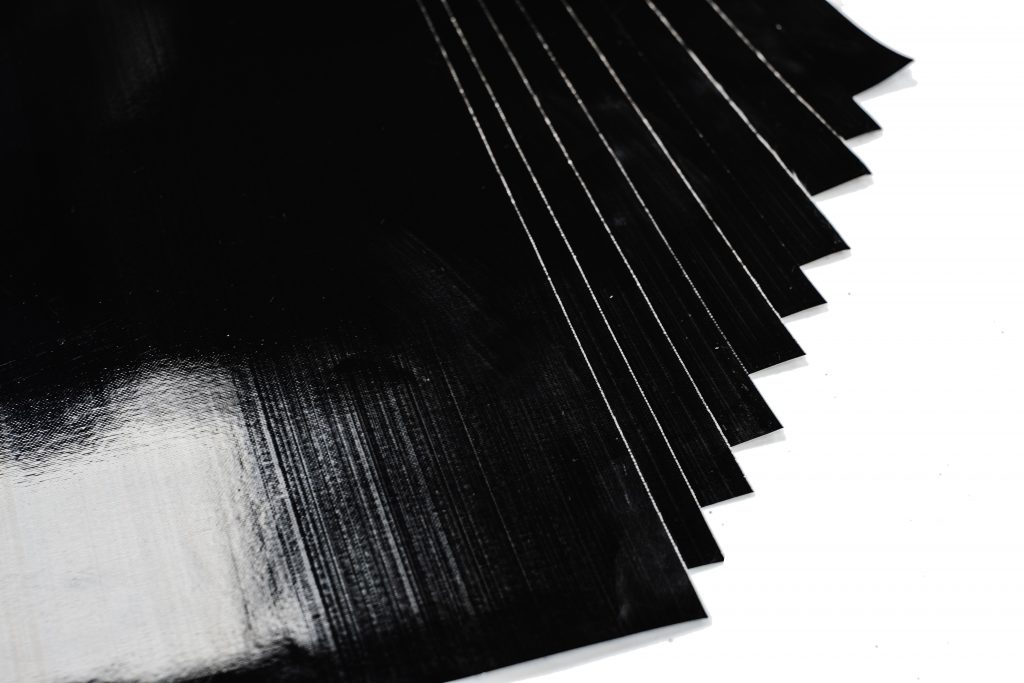

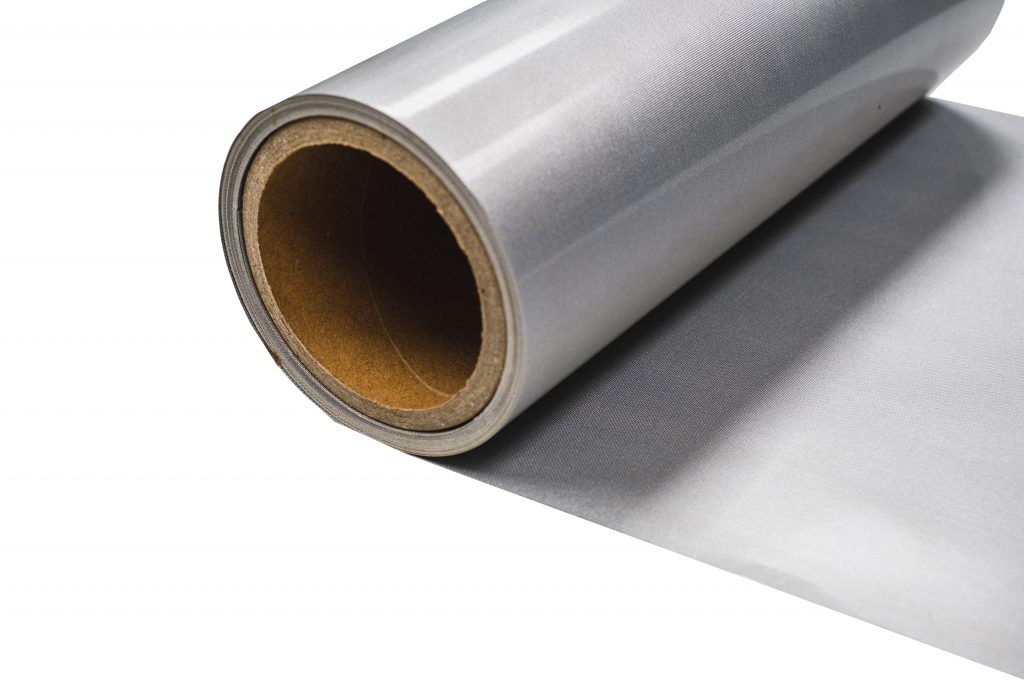

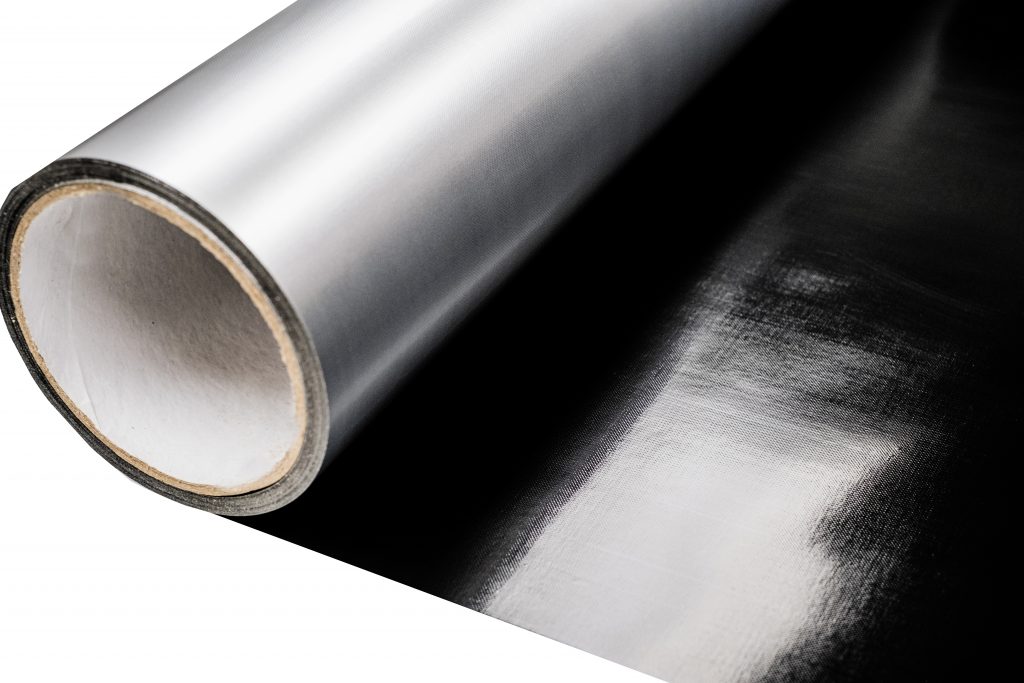

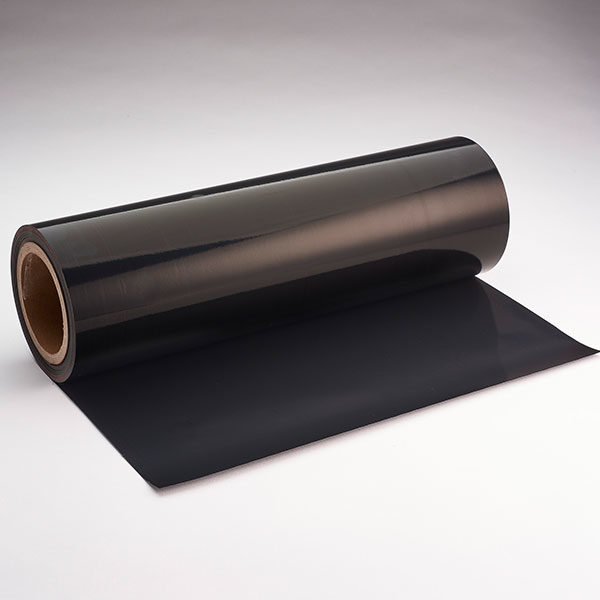

PTFE Fabrics & Mesh Rolls

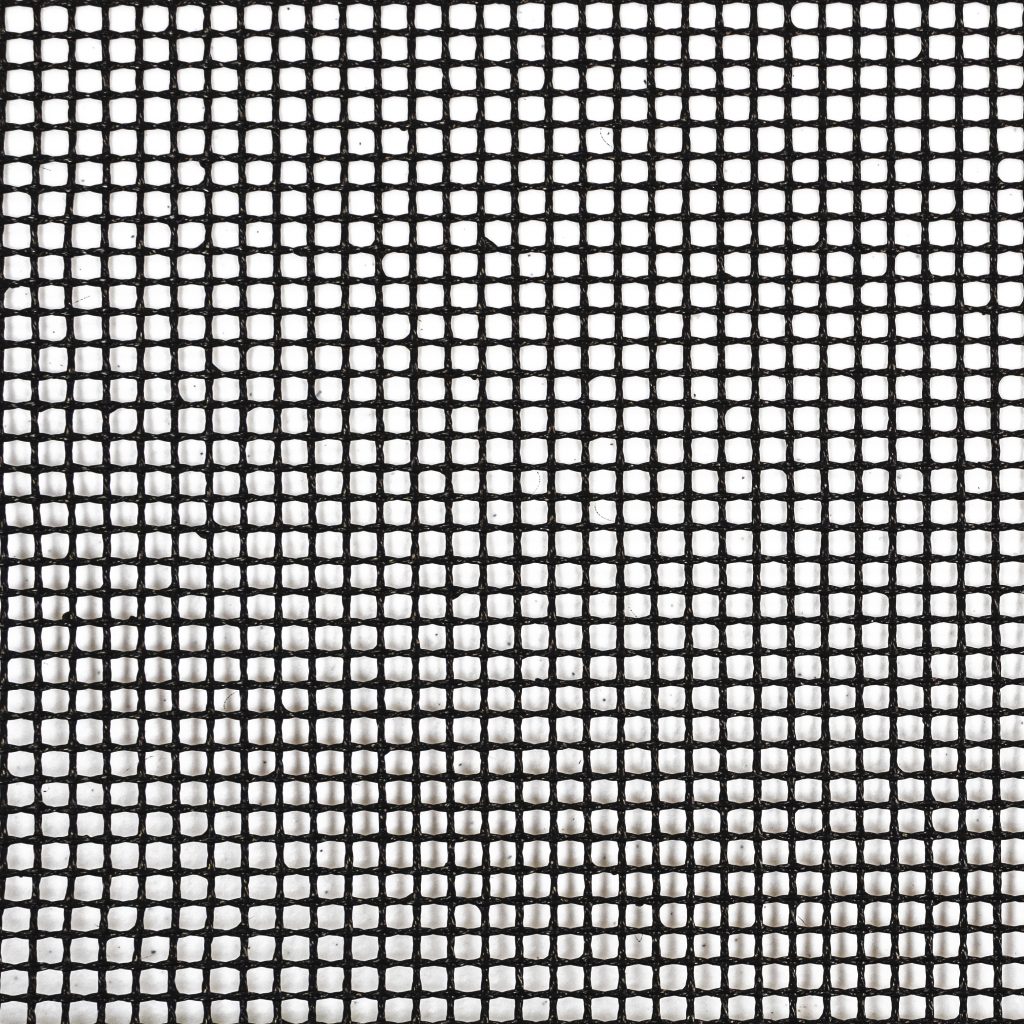

PTFE mesh fabric is manufactured from a PTFE coated fiberglass mesh and is commonly used in high temperature applications that require good air flow though the belt. The PTFE coating also provides excellent release properties making it popular for a wide range of product transfer and drying applications.

PTFE FABRICS & MESH SHEETS

Polytetrafluoroethylene (PTFE) sheets withstand chemicals and solvents better than most plastics. PTFE sheets remain stable at high temperatures and are non-conducting, so they’re ideal for electrical insulation and circuit boards.

Filter By

Product Categories

- Commercial Food Service (90)

- Custom Fabrics (14)

- Food Smoker/Pellet Grill Accessories (14)

- Grill Mitts (1)

- Industrial & Manufacturing (2)

- PTFE Baking Pan Liners (5)

- PTFE Baking Pan Liners (4)

- PTFE Flat Mesh (6)

- PTFE Mesh (23)

- Retail Grill and Smoker Accessories (1)

- Silicone Baking Mats (2)

- Specialty Graphics (40)

- 36 Yard Rolls (7)

- Heat Conductive Pads (2)

- Nomex Felt (1)

- Platen Wraps (5)

- PTFE Cover Sheets (17)

- PTFE Pressing Pillows (5)

- Uncategorized (2)

- Franchisee (2)

- Jack in the Box (1)

- Sonic (1)

- Franchisee (2)

Related Articles

Understanding the “New Normal” of Dining Commerce

The COVID-19 economy sweepstakes have a clear winner: groceries. What only a year ago was a tiny slice of the food industry pie has surged

October 12, 2021

No Comments

Understanding the Versatility of PTFE Coatings in the Commercial Kitchen

Both Technomic and Datassential project a steady rise in convenience store food service sales, driven by consumer demand for fresh, hot food options while refueling

April 17, 2025

No Comments

???? Introducing the Hottest Culinary Companion: Essentialware’s new FireMitt????

Are you ready to take your commercial food service to sizzling new heights? Look no further, because we’ve got the game-changer you’ve been waiting for

November 28, 2023

No Comments

FAQs

What are the industrial uses of PTFE coated fiberglass fabric?

PTFE coated fiberglass fabric has numerous industrial applications due to its non-stick properties, heat resistance, and chemical resistance. Its key industrial uses include:

- Food Processing: Conveyor belts for baking and cooking, oven liners, baking sheets and heat sealing of food packaging.

- Packaging Industry: Release sheets for heat sealing machines, conveyor belts for packaging lines, and heat shrink tunnels.

- Textile Industry: Digital printing processes, drying processes, and lamination of textiles.

- Chemical Industry: Gaskets and seals for equipment, protective clothing, and linings for tanks and pipes.

- Electrical Industry: Insulation for wiring and cables and circuit board manufacturing.

- Aerospace and Automotive: Heat shielding, insulation, and release fabrics for composite molding.

- Construction and Architecture: Tensioned membrane structures for architectural applications.

- Industrial Belting: Conveyor belts for many different industrial processes.

PTFE coated fiberglass fabric is essential in any industry requiring materials with exceptional heat resistance, chemical resistance and non-stick properties.

What are the different types of PTFE?

PTFE is generally classified as either filled or unfilled (virgin). Filled PTFE contains materials added to modify its mechanical and electrical properties. Common fillers may include fiberglass, carbon or graphite, which increase the strength of PTFE products while maintaining its core beneficial properties. Unfilled PTFE is virgin or pure PTFE without additives or fillers.

What is PTFE used for today?

PTFE is used in many applications requiring high temperature resistance, non-stick release properties, electrical insulation or chemical and weather resistance. Its versatility makes PTFE an invaluable material across numerous industries from food processing to aerospace. Perhaps the most well-known consumer application is non-stick cookware, with PTFE’s industrial applications more extensive and diverse.

Why is PTFE so expensive?

A key component of PTFE is fluorine. When considering where fluorine is most prevalent for mining, it’s crucial to focus on the mineral fluorite (fluorspar), which is the primary source.

Fluorite is primarily found in China, Mexico, Russia, South Africa, and Mongolia.

When considering the overall cost of PTFE, one must consider many factors including the mining and extraction of fluorite from specific regions, the cost of formulation of the chemical PTFE and the cost of manufacturing PTFE in its many forms such as sheets, rods, tubes, tapes and coatings. For example, manufacturing sheets of PTFE requires expensive specialized coating equipment and labor to operate the equipment.