Industrial PTFE Fabrics & Mesh Sheets

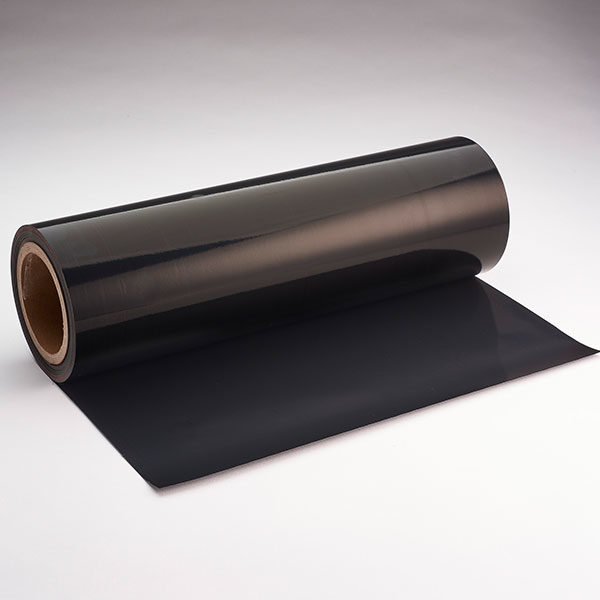

Polytetrafluoroethylene (PTFE) sheets withstand chemicals and solvents better than most plastics. PTFE sheets remain stable at high temperatures and are non-conducting, so they’re ideal for electrical insulation in circuit boards and for fabricating the electrostatic analogues of magnets. They are also nontoxic and suitable for food contact.

Here are some key aspects of non-stick PTFE for custom fabrics and industrial applications:

Non-Stick Properties: PTFE is renowned for its superior non-stick surface, making it suitable for applications where materials need to slide or release easily without sticking. This property minimizes friction and wear, enhances efficiency, and reduces the need for lubricants or release agents.

High-Temperature Resistance: PTFE materials can withstand extreme temperatures, often exceeding 500°F (260°C) without degrading. This characteristic is crucial for applications involving heat sealing, welding, baking, or any process with high-temperature exposure.

Chemical Resistance: PTFE is highly resistant to a wide range of chemicals, acids, and solvents. This resistance ensures that PTFE materials remain unaffected by exposure to corrosive substances, which is vital in chemical processing and industrial environments.

Electrical Insulation: PTFE is an excellent electrical insulator, making it valuable in applications that require electrical insulation, such as wire and cable insulation, gaskets, and electronic components.

Durability: Non-stick PTFE materials are known for their durability and resistance to wear and tear. They have a long service life, reducing the need for frequent replacements.

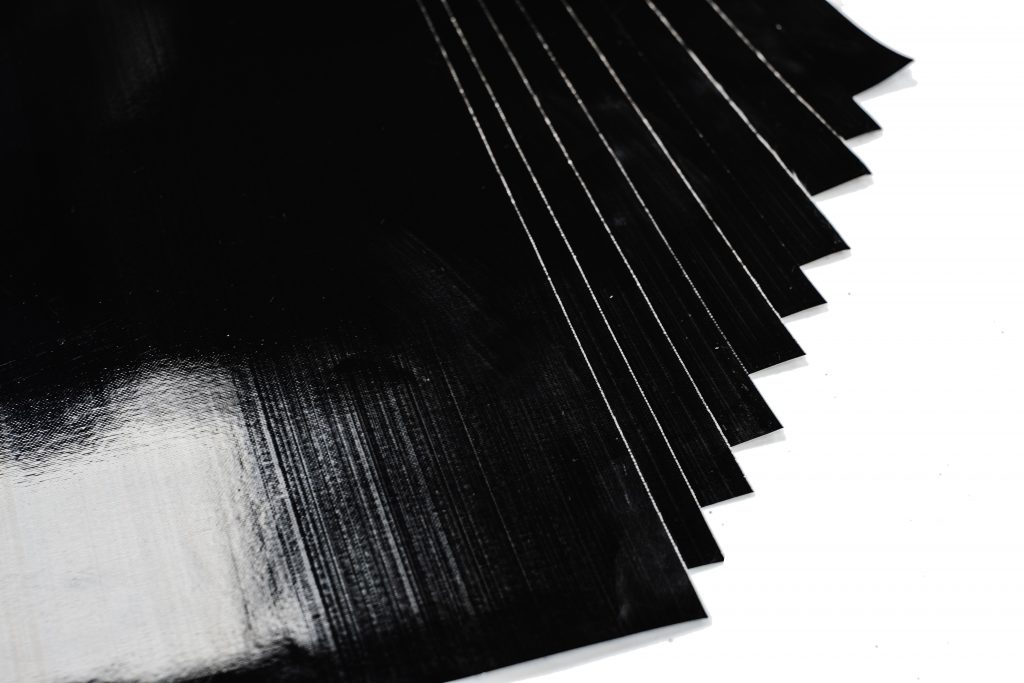

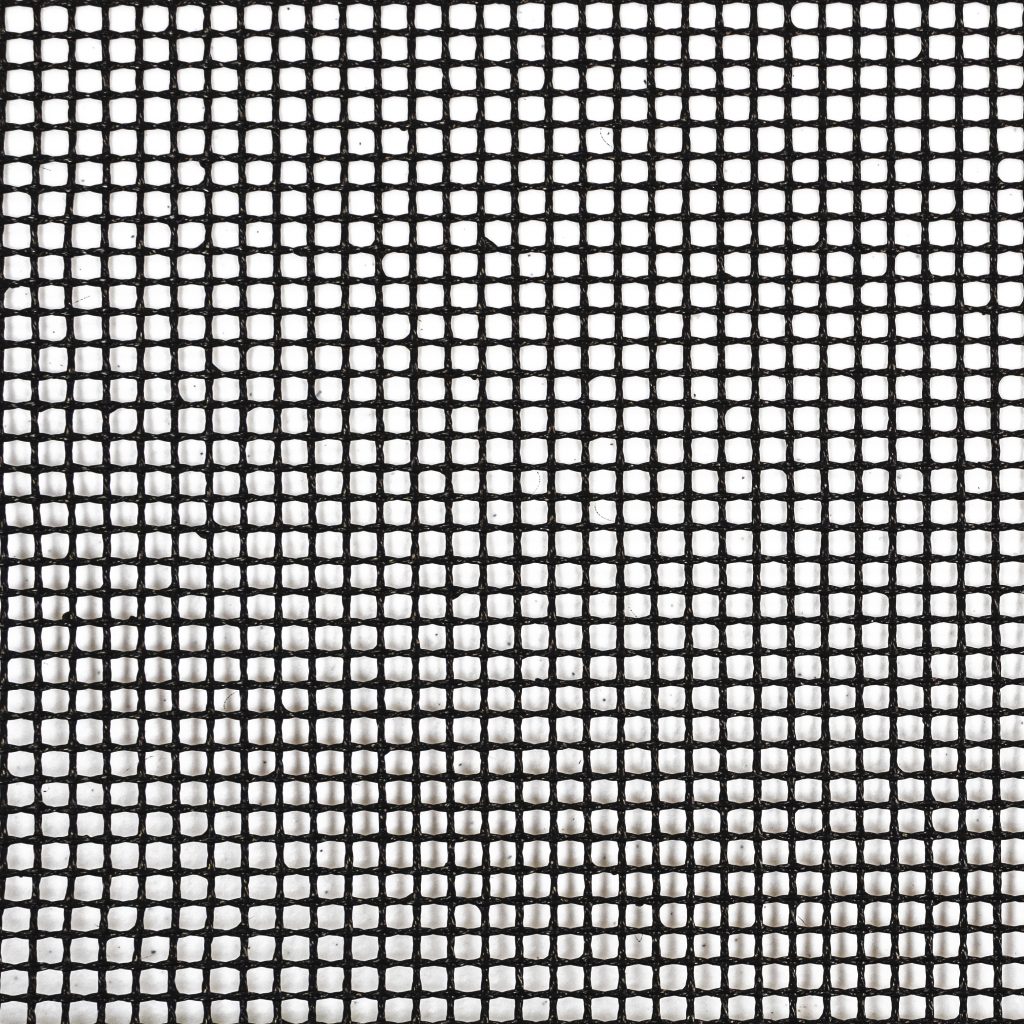

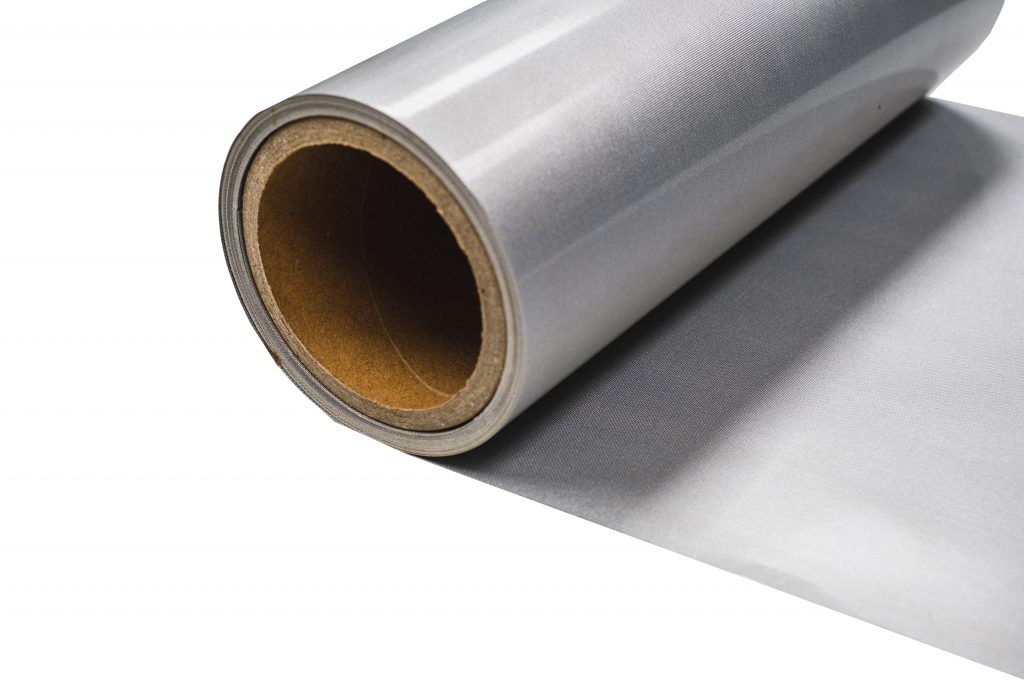

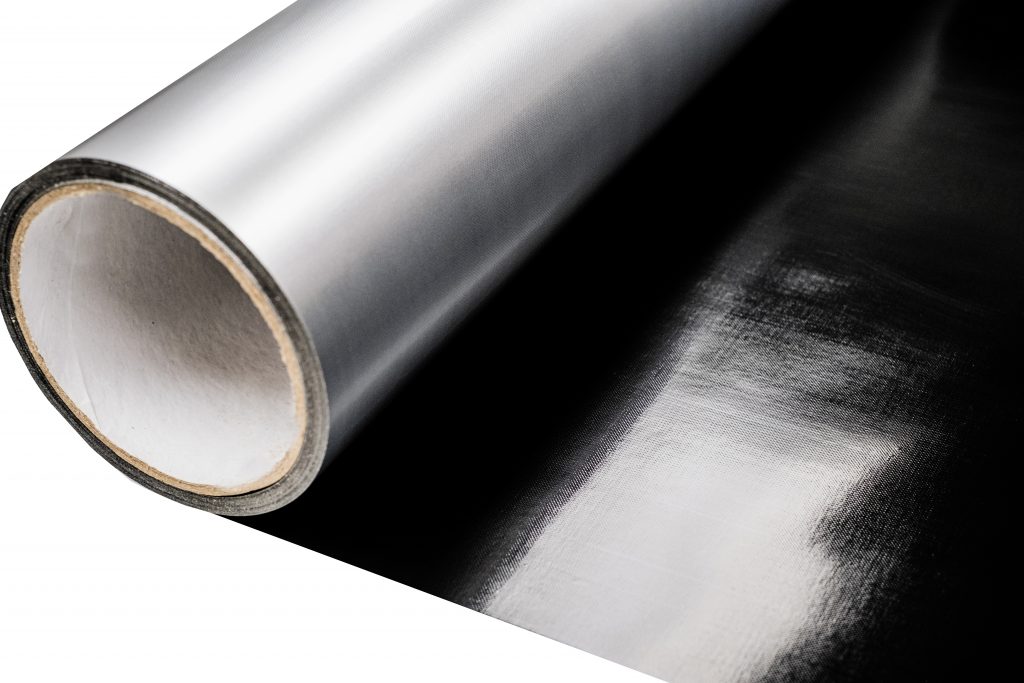

Versatility: PTFE materials are available in various forms, including sheets, films, tapes, and custom shapes. They can be easily customized and fabricated to meet specific industrial requirements.

Filter By

Product Categories

- Commercial Food Service (87)

- Custom Fabrics (14)

- Food Smoker/Pellet Grill Accessories (11)

- Grill Mitts (1)

- Industrial & Manufacturing (2)

- PTFE Baking Pan Liners (5)

- PTFE Baking Pan Liners (4)

- PTFE Flat Mesh (6)

- PTFE Mesh (23)

- Retail Grill and Smoker Accessories (1)

- Silicone Baking Mats (2)

- Specialty Graphics (40)

- 36 Yard Rolls (7)

- Heat Conductive Pads (2)

- Nomex Felt (1)

- Platen Wraps (5)

- PTFE Cover Sheets (17)

- PTFE Pressing Pillows (5)

Related Articles

2020 Fast Track 50 Winners Announced

The staff of Essentialware and family are pictured for the Fast Track 50 Award. Top Row, left to right: Cindy Moore, Kathleen Marria, Danielle

October 12, 2020

No Comments

Spring Asparagus Grilled Pizza | Vegan, Vegetarian, or Omnivore

Spring Asparagus Grilled Pizza | Vegan, Vegetarian, or Omnivore Spring Asparagus Grilled Pizza is something of a surprise hit. I’ve tried this out on all

February 12, 2022

No Comments

Adaptation and Innovation: Food Service Dealers Looking Beyond 2020

Adaptation and Innovation: Food Service Dealers Looking Beyond 2020 This is Part 1 of a multi-part series, in which we’ll explore innovations already underway in

November 12, 2020

No Comments