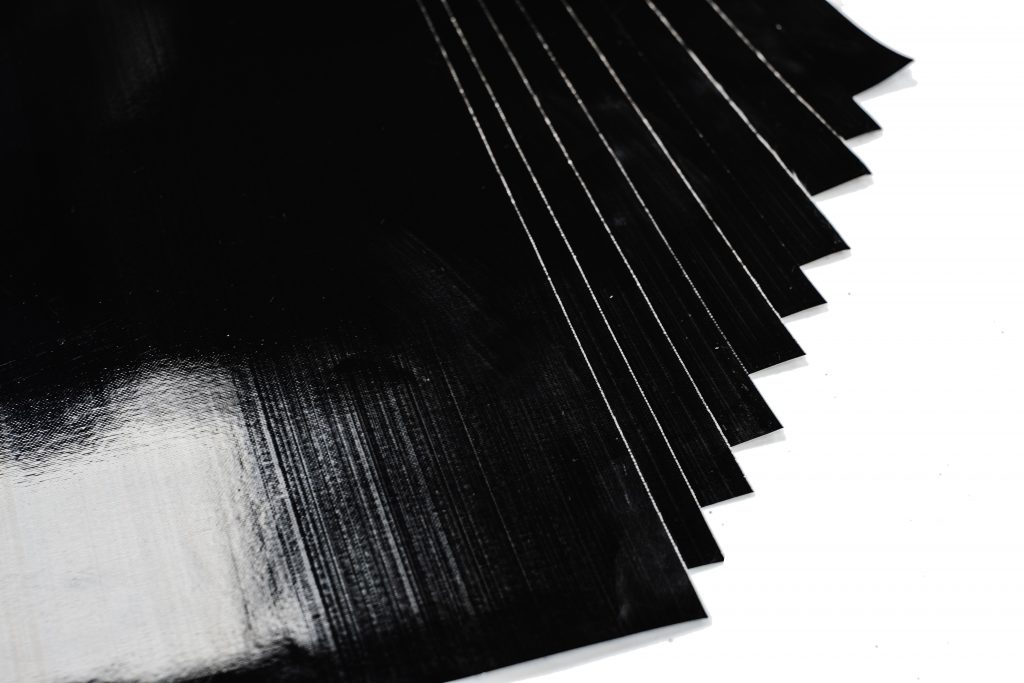

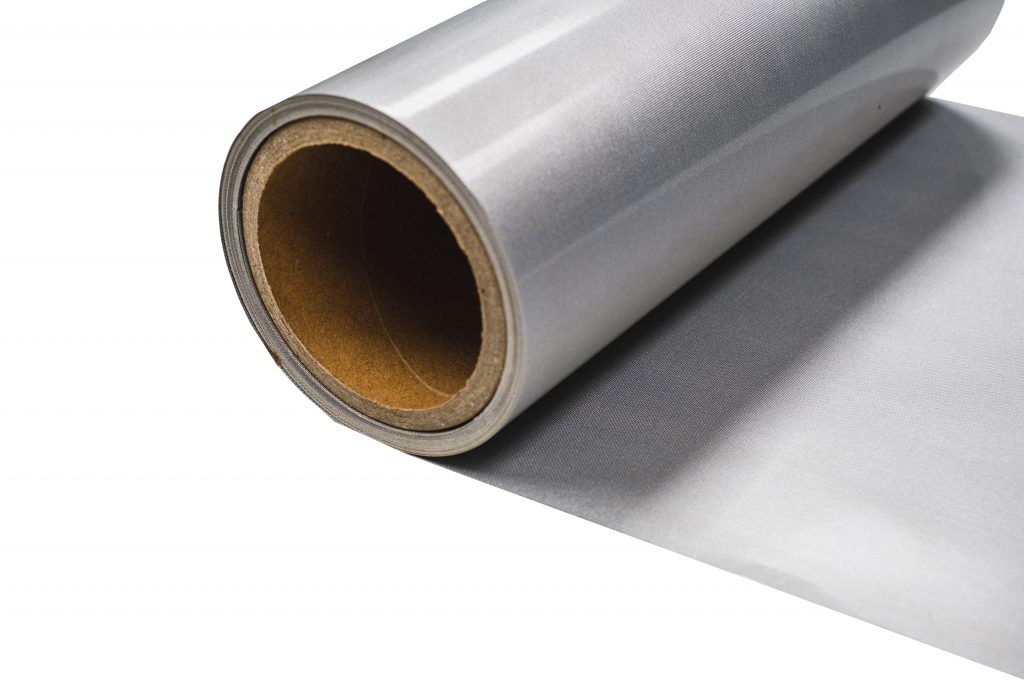

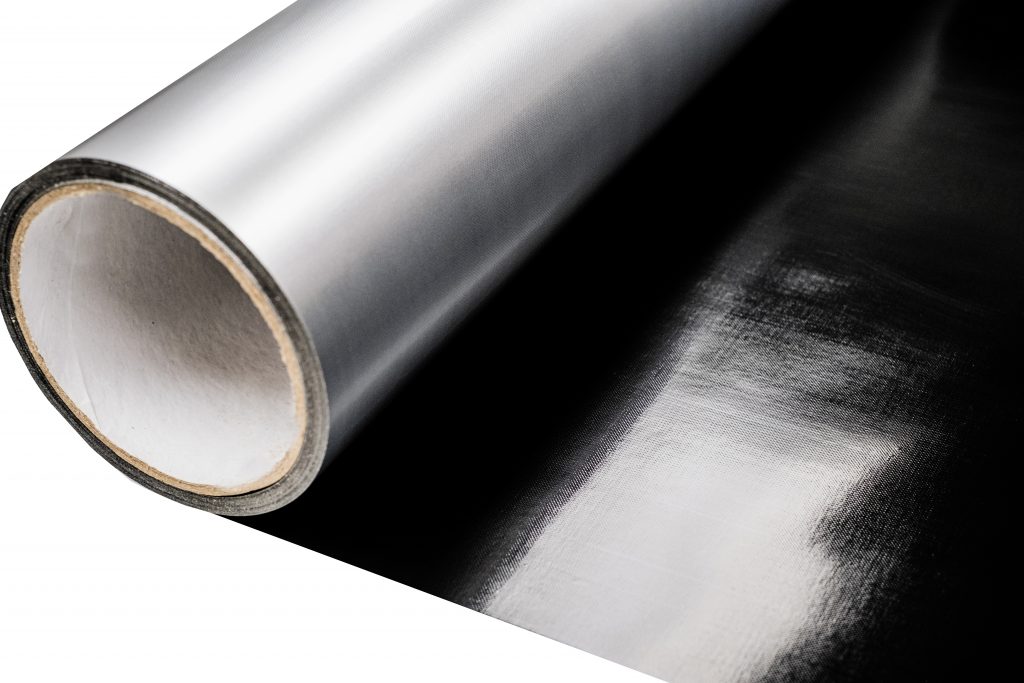

Industrial PTFE Fabrics & Mesh Rolls

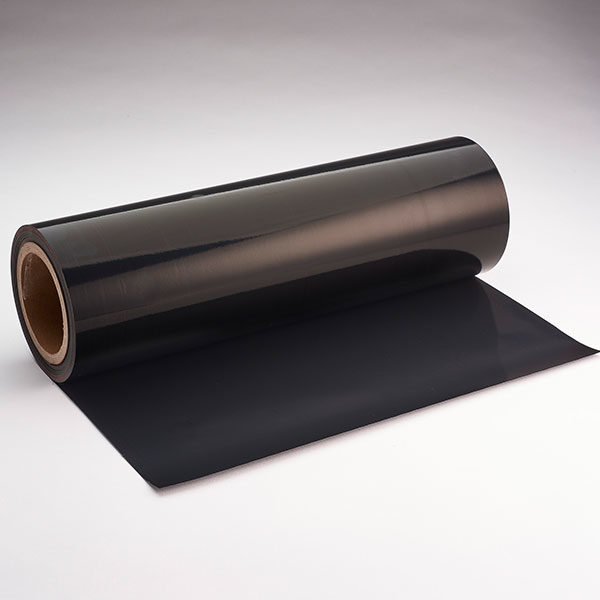

Non-stick PTFE (Polytetrafluoroethylene) materials are highly valued in custom fabrications and various industrial applications due to their exceptional non-stick, high-temperature resistance, and chemical resistance properties. These materials provide unique advantages in manufacturing, processing, and production environments.

Common industrial applications of non-stick PTFE materials include:

Seals and Gaskets: PTFE gaskets and seals are used in industries where chemical resistance, non-stick properties, and high-temperature resistance are essential, such as in chemical processing, petrochemical, and pharmaceutical industries.

Conveyor Belts: PTFE conveyor belts are used in food processing, packaging, and industrial applications to transport materials through high-temperature processes without sticking.

Release Liners: PTFE release liners are employed in adhesive tape and label manufacturing, ensuring that adhesive materials do not stick to the backing during storage and application.

Heat Sealing: PTFE films and tapes are used in heat sealing applications to prevent materials from adhering to heated surfaces during sealing processes.

Expansion Joints: PTFE expansion joints are utilized in pipelines and ducts to accommodate thermal expansion, resist corrosion, and maintain a non-stick interior surface.

Textile Industry: PTFE-coated fabrics are employed in the textile industry for applications such as conveyor belts, fusing presses, and heat-sealing equipment.

Filter By

Product Categories

- Commercial Food Service (87)

- Custom Fabrics (14)

- Food Smoker/Pellet Grill Accessories (11)

- Grill Mitts (1)

- Industrial & Manufacturing (2)

- PTFE Baking Pan Liners (5)

- PTFE Baking Pan Liners (4)

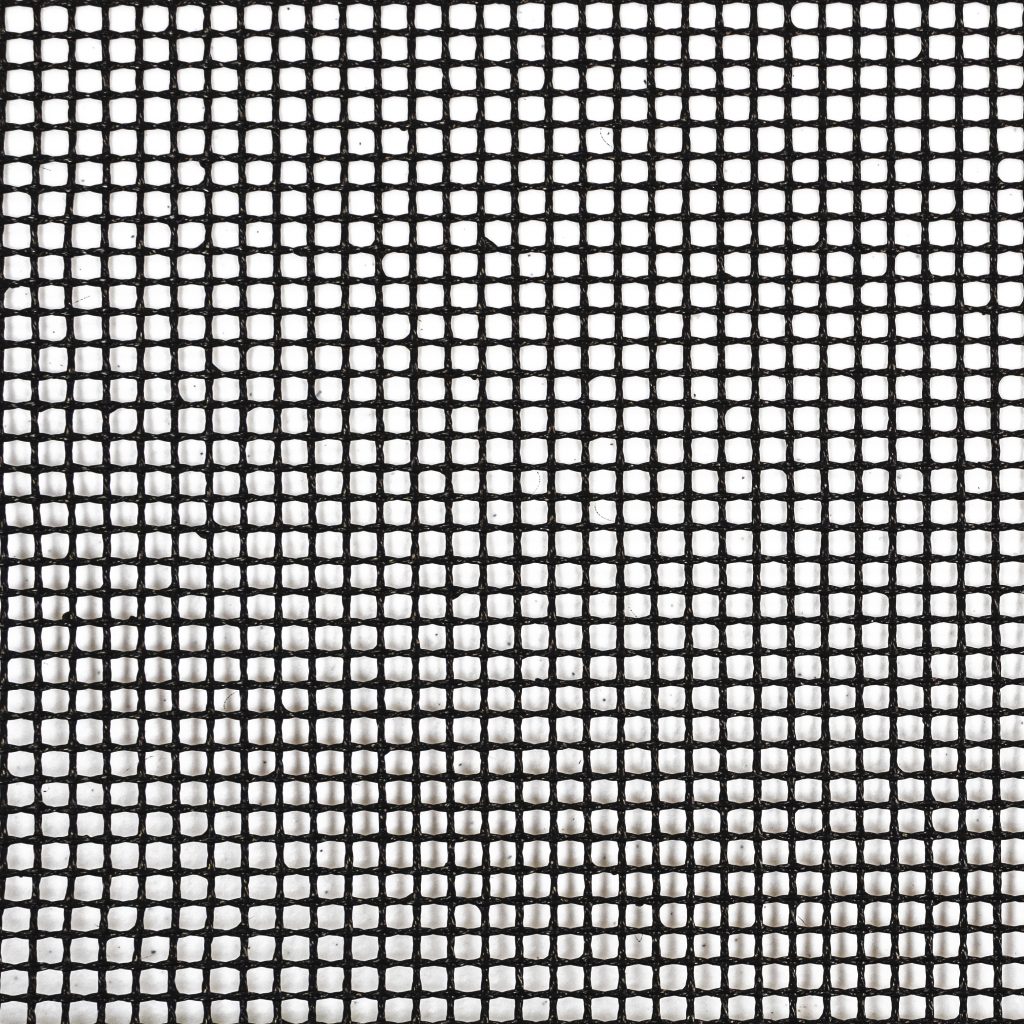

- PTFE Flat Mesh (6)

- PTFE Mesh (23)

- Retail Grill and Smoker Accessories (1)

- Silicone Baking Mats (2)

- Specialty Graphics (40)

- 36 Yard Rolls (7)

- Heat Conductive Pads (2)

- Nomex Felt (1)

- Platen Wraps (5)

- PTFE Cover Sheets (17)

- PTFE Pressing Pillows (5)

Related Articles

2020 Fast Track 50 Winners Announced

The staff of Essentialware and family are pictured for the Fast Track 50 Award. Top Row, left to right: Cindy Moore, Kathleen Marria, Danielle

October 12, 2020

No Comments

* What a Grill Wants: 6 Excellent Grill Gifts for any Holiday

What A Grill Wants: 6 Excellent Grill Gifts for Any Holiday We’ve rounded up our favorite grill gifts, gadgets, and gear. Covering a wide range

July 12, 2022

No Comments

How to secure up to $10million with the RRF

What is the RRF, what does it mean for me? On May 3rd, the Restaurant Revitalization Fund (RRF) program will provide restaurants with funding equal

March 12, 2022

No Comments